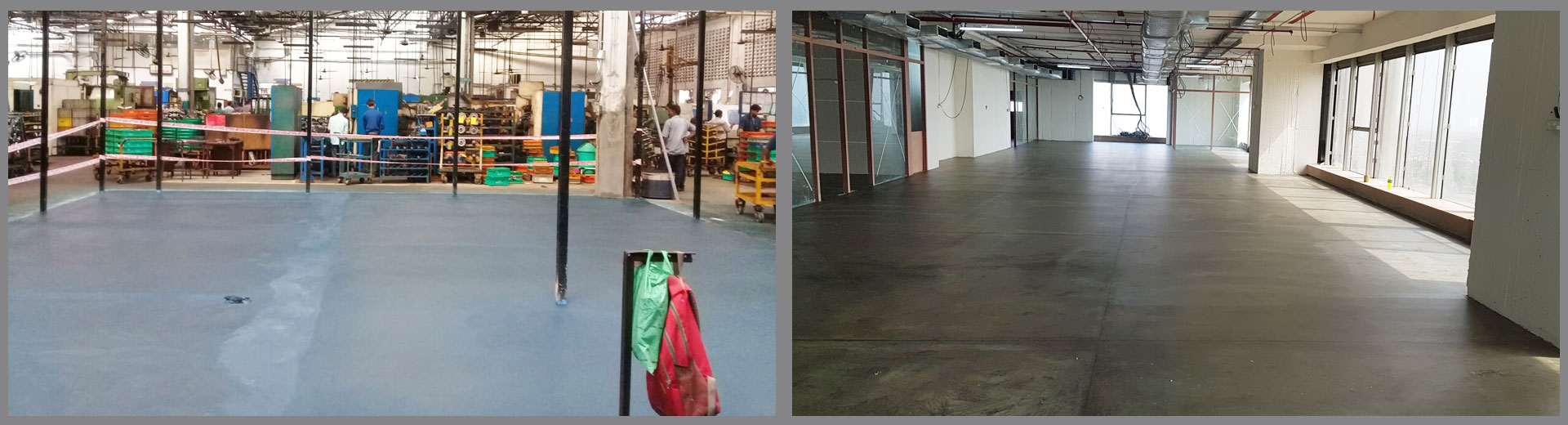

Factory Flooring Solutions

Industrial Grade Strength | Hygienic | Long Lasting Powered by Chemoxy Flooring

In modern manufacturing and processing environments, the factory floor does much more than support operations it defines them. At Chemoxy Flooring, we specialize in delivering factory flooring solutions that combine strength, safety, hygiene, and efficiency. Whether you manage a food processing plant, a heavy engineering facility, or a pharmaceutical factory, our flooring systems are engineered to meet the toughest operational demands

We don-t just build floors we build foundations for safer, more productive workspaces.

What is Factory Flooring?

Factory flooring refers to robust, industrial-grade flooring systems specifically designed to perform in high-traffic, high-impact, and often chemically aggressive environments. These floors are meant to withstand the weight of heavy machinery, resist spills and chemicals, ensure hygiene, and minimize maintenance all while complying with safety and operational regulations.

With Chemoxy Flooring, you get flooring systems that are purpose built, long-lasting, and tailored to your exact industry needs.

Types of Factory Flooring Solutions We Offer

Every factory is unique, and so are its flooring needs. That's why we offer a comprehensive range of flooring systems:

• 1.Chemoxy OSR Floorings

• 2.Chemoxy WR Floorings

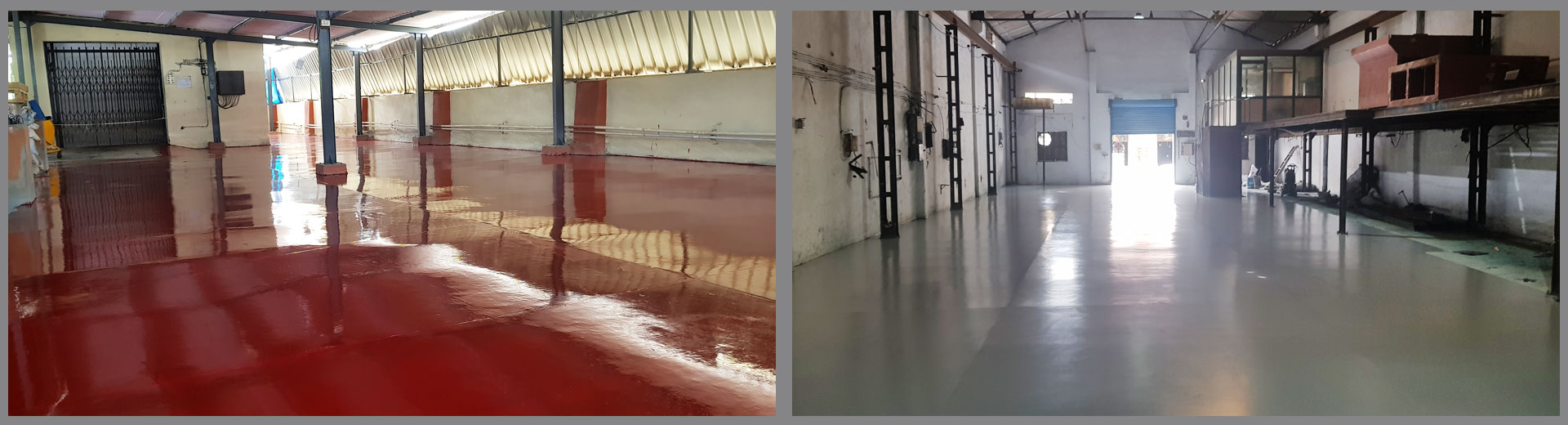

• Epoxy Flooring

•Ideal for factories requiring a smooth, joint-free, and chemical-resistant surface. Epoxy coatings are seamless, dust-proof, and easy to clean perfect for general industrial use.

• PU (Polyurethane) Flooring

• Known for its thermal shock resistance and elasticity, PU flooring is a favorite in food, beverage, and cold storage environments where temperature fluctuations are common.

• Anti-Static / ESD Flooring

• Designed for electronics, pharmaceutical, and cleanroom applications where electrostatic discharge poses risks. These systems control static build-up and ensure compliance with ESD safety standards.

• Concrete Polishing & Densification

• An economical, low-maintenance option for large industrial zones. Offers increased surface hardness and aesthetic appeal without coating layers.

• Hybrid Systems

• Custom solutions like epoxy mortar or PU concrete (PUC) that combine strength, shock absorption, and chemical resistance for the most demanding factory conditions.

Key Features & Benefits

Our factory flooring solutions are designed to deliver performance where it matters:

• High Load-Bearing Capacity: Supports forklifts, trolleys, and machinery with ease

• Abrasion & Impact Resistance: Withstands daily wear and heavy-duty operations

• Slip Resistance: Textured finishes ensure worker safety in wet/oily zones

• Chemical & Oil Resistance:Durable against acids, alkalis, and solvents.

• Hygienic & Seamless: Easy to clean and compliant with food and pharma standards

• Quick Curing: Fast turnaround with minimal disruption

• Customizable Aesthetics: Choose from a range of finishes and demarcation options

Industry Applications

Chemoxy Flooring has installed flooring in a wide range of factories and processing units across India:

• Automotive & Engineering Plants

• Food & Beverage Factories

• Pharmaceutical & Biotech Facilities

• Chemical & Petrochemical Units

• Textile & Garment Industries

• Packaging, Plastics & Printing Factories

• Heavy Manufacturing & Foundries

Why Choose Chemoxy Flooring?

With years of hands-on industry experience and a commitment to quality, Chemoxy Flooring has become a trusted name in industrial flooring. Here's what sets us apart:.

• Certified Materials: ISO-compliant products and tested application systems

• Expert Installation: In-house trained applicators and efficient project planning

• End-to-End Support: From site inspection to after-sales guidance

• Proven Track Record: Hundreds of successful installations across India

• Affordable & Reliable:Long-lasting systems that offer excellent ROI

Our Installation Process

We follow a systematic approach to every flooring installation:.

• Site Assessment & Free Site Inspection

• Surface PreparationSubstrate Evaluation & Moisture Testing

• Flooring ApplicationSurface Preparation-Shot blasting, grinding, patching

• Curing ProcessApplication of Primer & Base Layers

• Final Coating / Finish Layer

• Curing, Testing & Handover

We ensure minimal disruption to your operations and complete transparency throughout the process.

Maintenance Guidelines

• To ensure your factory floor remains in excellent condition for years:

• Clean regularly using neutral-pH industrial cleaners

• Avoid dragging heavy objects without protection

• Promptly clean chemical spills

• Schedule annual inspections for wear and tear

• Recoat high-impact areas every 5-7 years as needed

• Our team can also recommend a preventive maintenance schedule post-installation.

Frequently Asked Questions (FAQs)

Q1: Which flooring is best for heavy machinery factories?

A: Chemoxy OSr Flooring and Chemoxy WR Flooring Epoxy mortar or PU concrete (PUC) systems are highly recommended for their durability and impact resistance.

Q2: How long does it take to install factory flooring?

A: Depending on the size and type, most installations are completed within 3-7 working days.

Q3: Is your flooring suitable for pharma cleanrooms?

A: Yes, we offer seamless, anti-microbial, and dust-free flooring that complies with cleanroom and GMP requirements.

Q4: What about food-grade flooring?

A: Our flooring solution is ideal for food and beverage industries, offering resistance to oils, fats, and temperature variations.

Q5: Do you offer warranties?

Get Started with Chemoxy Flooring

Whether you're constructing a new facility or upgrading an old floor, Chemoxy Flooring delivers flooring systems that last, perform, and protect.

Your factory deserves a floor that works as hard as you do. Let's build it together.

- Chemoxy OSR Flooring: Ideal for forklift-heavy and chemical-prone zones.

- Chemoxy WR Flooring: High abrasion and water-resistant option.

- Epoxy & PU Coatings: Seamless, aesthetic, and cost-effective for general-purpose use.

Frequently Asked Questions (FAQs)

Q1: Which flooring type is best for forklift-heavy traffic?

A: Chemoxy OSR Flooring or Chemoxy WR Flooring, Epoxy or PU flooring are ideal due to their load resistance and surface toughness.

Q2: How long does the installation process take?

A: Depending on the area, we can complete most jobs within 3-7 days.

Q3: Can you install flooring in active warehouse environments?

A: Yes, with proper planning, we can work in phases to avoid full shutdowns.

Q4: What is the lifespan of your warehouse flooring?

A: Typically 10-15 years with proper maintenance.

Q5: Is anti-slip flooring available?

A: Absolutely! All our systems can be customized with textured, anti slip finishes.

Ready to Upgrade Your Warehouse Floor?

At Chemoxy Flooring, we're committed to engineering floors that match your vision and exceed your expectations. Whether you're upgrading an old warehouse or building a new facility, we're here to support you every step of the way.

Contact us now for a free site inspection, personalized quote, and sample recommendations